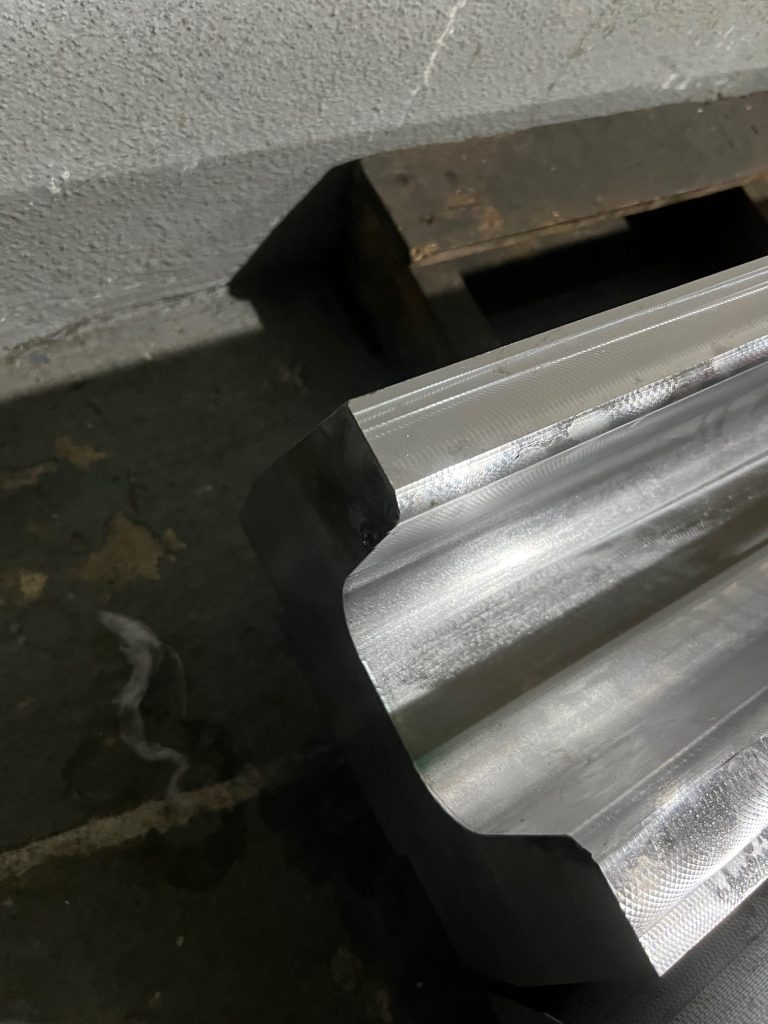

The press brake tools custom-manufactured by our company for our client have been delivered after successfully passing quality control processes. These press brake dies are designed to provide high precision, long service life, and repeatable bending performance.

High Strength – Precise Bending – Long Service Life

The manufactured press brake tools feature:

High-strength tool steel

Surface treatments to increase resistance to wear

Sharp corner and angle tolerances that minimize bending errors

Thanks to these features, they offer a reliable solution for both mass production and custom part bending applications.

Engineering-Oriented Approach in Press Brake Tool Manufacturing

Each project is planned based on engineering calculations, taking into account:

The type of press brake machine used

The thickness and type of the material to be bent

The required angle and bending geometry

Production quantities

This approach reduces the risk of bending errors while increasing production speed and quality.

Manufacturing and Quality Process

High-precision machining on CNC machines

Dimensional and angular inspections

Functional compatibility tests

Secure packaging and shipment

Thanks to these processes, the delivered press brake tools operate stably and smoothly from first use.

Areas of Application

The press brake tools we manufacture are safely used in many sectors, including:

Sheet metal bending applications

Automotive sub-industry

Machinery manufacturing

Industrial constructions