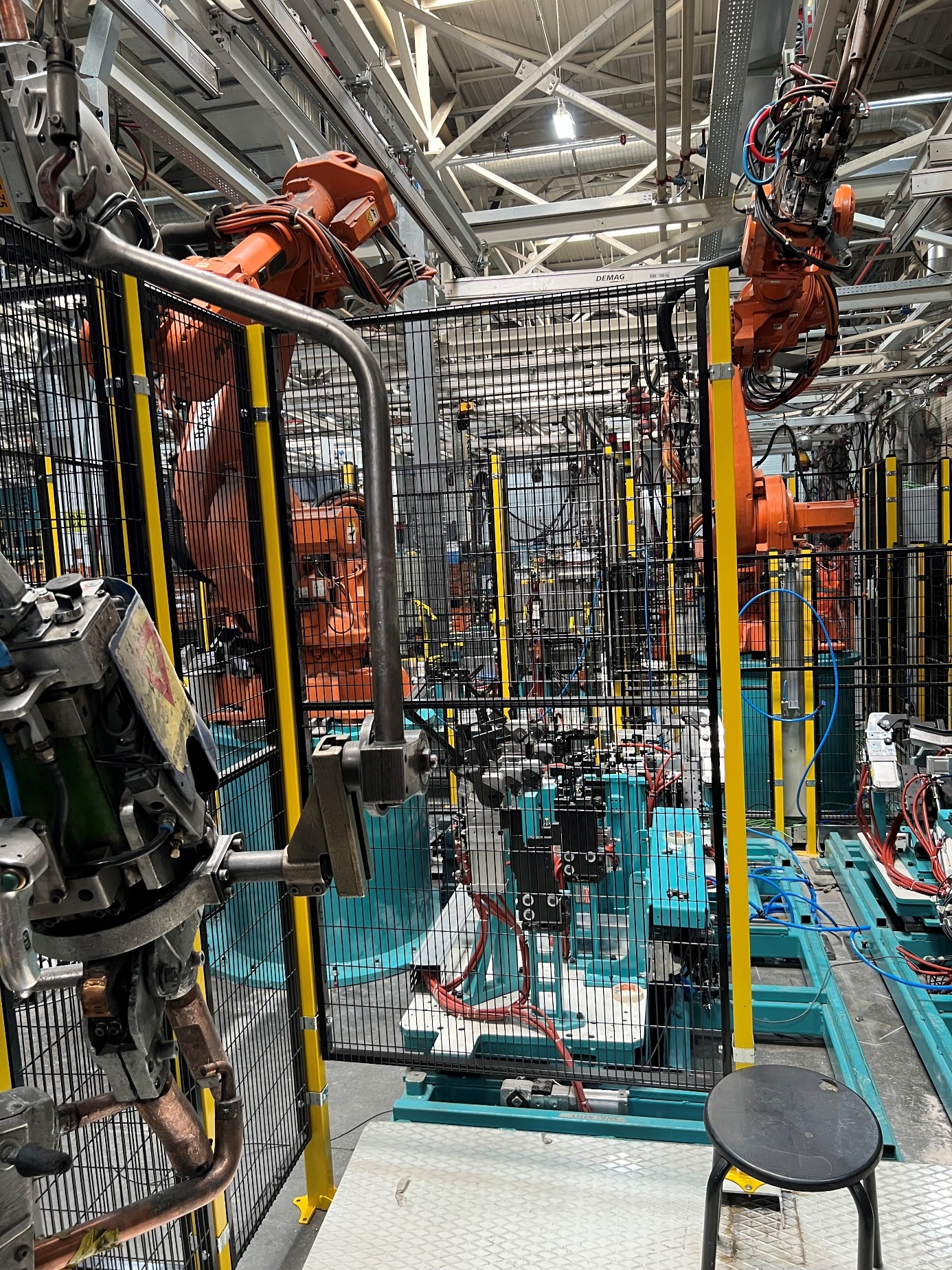

As FABALP Makine, we have successfully completed our new project that transforms manual welding processes into automation. In this scope, 4 custom-designed welding fixtures and 3 industrial welding robots have been put into production after integration and commissioning phases.

One of the main goals of the project was to integrate all previously manual spot welding operations into robotic welding systems, thereby increasing both quality and efficiency on the production line.

🔧 Project Summary

🛠️ Comprehensive Automation Transformation:

- 4 custom-designed welding fixtures (pneumatic clamping + precise positioning)

- 3 robotic welding stations (ABB robots + welding power units)

- All systems tested in the Process Simulate environment

- Manual spot welding operations fully robotized

- Successfully commissioned in our customer’s production line

📐 Design and Engineering Process

Fixtures were specifically designed based on weld points, clamping positions, and welding sequence of the parts. Robot reach scenarios and movement zones on fixtures were verified in a digital environment using Process Simulate.

💡Analyses conducted:

- Robot reach and collision simulations

- Welding sequence and cycle time calculations

- Operator accessibility and maintenance ease

- Production cycle time optimization

🏭 Manufacturing and Commissioning

Manufacturing and assembly were carried out step-by-step in-house at FABALP:

- Welding and CNC machining of fixture bodies

- Integration of pneumatic clamping systems

- Installation and cabling of robotic welding units

- Assembly of HMI and control panels

- On-site commissioning, synchronization testing, and trial production

- Operator training and technical documentation delivery

All components were tested in the workshop before commissioning and calibrated according to field conditions.

🎯 Benefits of Transitioning from Manual to Robotic

Thanks to this transformation, the following contributions were made to the production process:

✅ Minimized human error

✅ Improved weld quality and repeatability

✅ Significantly reduced cycle time

✅ Reduced operator requirement

✅ Standardized and traceable production process

🌍 Application Areas

This project is a strong example for high-volume manufacturers. When manual spot welding operations are transformed into robotic systems, the following industries gain significantly:

🚗 Automotive component manufacturing

🏗️ Heavy industry component assembly

🦾 Robotic welding cells

📦 Metal body and casing production

🔧 What FABALP Makine Offers

FABALP Makine provides more than just component production. We offer integrated services including end-to-end automation integration, fixture design, robot programming, simulation, on-site commissioning, and operator training.

As in this project, we deliver all processes with our in-house engineering power on a turnkey basis.

📩 For more information or a quote, contact us at:

info@fabalp.com

🌐 www.fabalp.com