As FABALP Makine, we are proud to have successfully completed another project! The robot base we designed and manufactured specifically for industrial automation infrastructure has passed all quality and durability tests and has been delivered to our client.

🔧 Project Details

The robot base produced within the scope of this project is optimized for welding robots and automation systems. It is used in a production facility in the automotive sector.

🛠️ Technical Specifications:

- Material: ST37 steel body

- Top Plate: Milled with ±0.1 mm precision

- Surface Treatment: Sandblasting + paint

- Robot Brand: ABB

- Additional Details: Internal cable ducts and service access panels

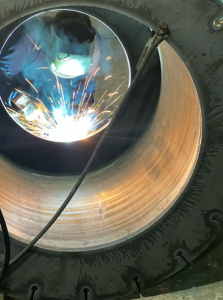

📸 Images from the Project

💡 Why a Custom Robot Base?

Each production environment has unique needs. Thanks to a tailor-made robot base:

✅ Maximum robot reach is achieved

✅ Vibration-induced position shifts are prevented

✅ Easy assembly and maintenance access

✅ Adds both function and aesthetic to the robotic cell

📐 Design & Manufacturing Process

We conducted RobotStudio and FEM (Finite Element Method) analysis for robot reach and load distribution. The production stages included:

🔹 Welded fabrication

🔹 CNC machining

🔹 Surface preparation

🔹 Painting and quality control

We followed our usual “design > analysis > production > control > delivery” workflow.

🌍 Applications

Such custom-made robot bases are used in many industries, particularly the automotive industry:

🚗 Welding robot base

📦 Palletizing robot base

🔩 Assembly and screwing systems

🦾 Vision systems with high precision

🏭 Press line robot integration

💬 Customer-Focused Solutions

At FABALP, we offer custom engineering services for every project. Whether a single robot base or a full robotic cell—tell us your vision, we make it real.

📞 Contact us:

👉info@fabalp.com

👉www.fabalp.com