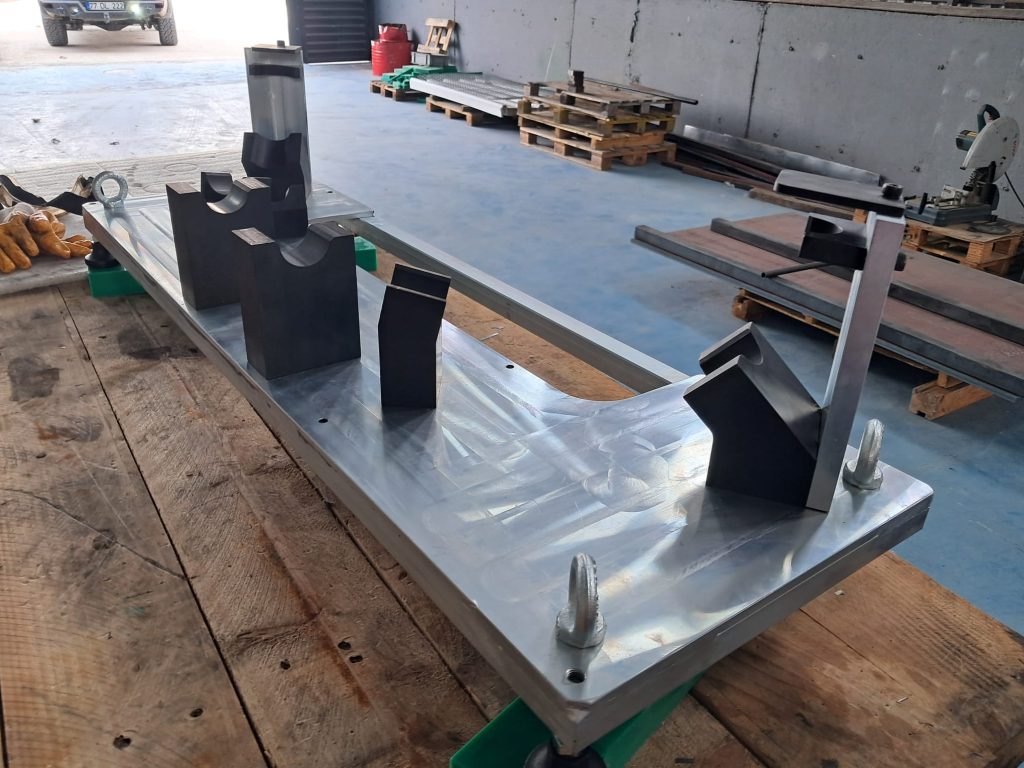

As FABALP Machine Industry and Trade Inc., we are proud to have successfully completed another control fixture project. Designed, manufactured, assembled, and calibrated entirely in-house, this fixture has been delivered for use on our customer’s production line.

About the Project

This control fixture was designed to verify the geometric accuracy of a highly precise part. It combines the following functions in a single compact structure:

- Post-welding dimension verification

- Assembly fit inspection

- Reference surface determination

The fixture uses ST52 steel, aluminum measurement arms, and precision gauge pins. Each component was tested with a Coordinate Measuring Machine (CMM) and delivered with measurement certificates.

Design and Manufacturing Process

FABALP’s engineering team analyzed the customer’s CAD data and developed a custom design using CATIA V5. All mounting points, measuring zones, and reference surfaces were modeled with perfect data alignment.

After CNC machining, assembly, surface grinding, and calibration, the fixture was delivered on schedule.

Customer Delivery and Quality Approval

The control fixture successfully passed both internal quality control and customer approval tests prior to delivery.

- ±0.05 mm accuracy was achieved at all measurement points.

- A 100% compliance report was obtained with zero errors detected during assembly.

- The fixture’s ergonomics were verified with user-friendly operation and ease of use.

Upon delivery, the customer was also provided with operating and maintenance instructions, a calibration certificate, and design data (in PDF and STEP formats).

Engineering You Can Trust

At FABALP, we combine experience and precision in welding, assembly, and control fixtures, including robotic welding cells. Each control fixture we produce strengthens our clients’ quality assurance processes.

This project reinforces our mission to deliver solutions that improve production quality, reduce inspection time, and ensure operator-independent verification.

Secure the Future with FABALP

Each project brings us closer to the future of precision and automation in industrial manufacturing.

FABALP continues to offer custom solutions for:

- Welded part control fixtures

- Automotive part inspection fixtures

- Sheet metal checking fixtures

- Assembly control fixtures

Our latest delivery once again reflects FABALP’s engineering discipline, quality standards, and commitment to customer satisfaction.