In modern industrial manufacturing facilities, robotic welding cells play a critical role in achieving high-quality standards, repeatable welding precision, and optimized process efficiency. Particularly in the automotive and railway industries, robotic Gas Metal Arc Welding (GMAW) systems significantly increase production speed while minimizing quality variations.

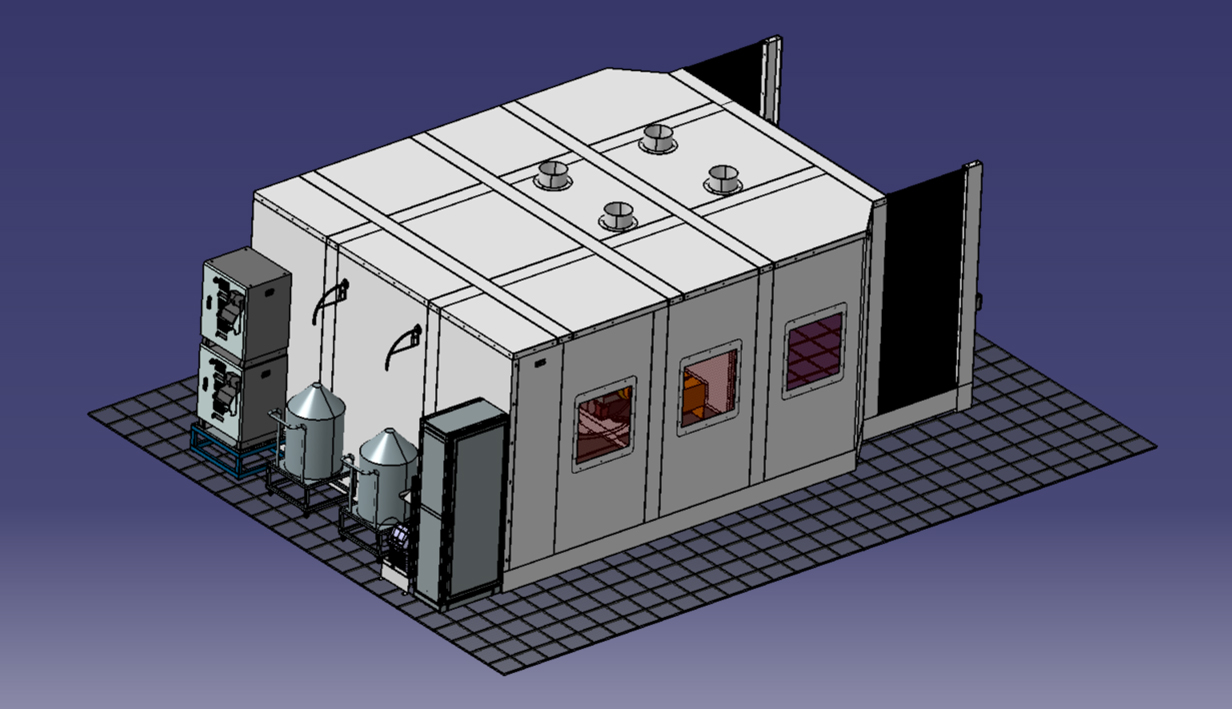

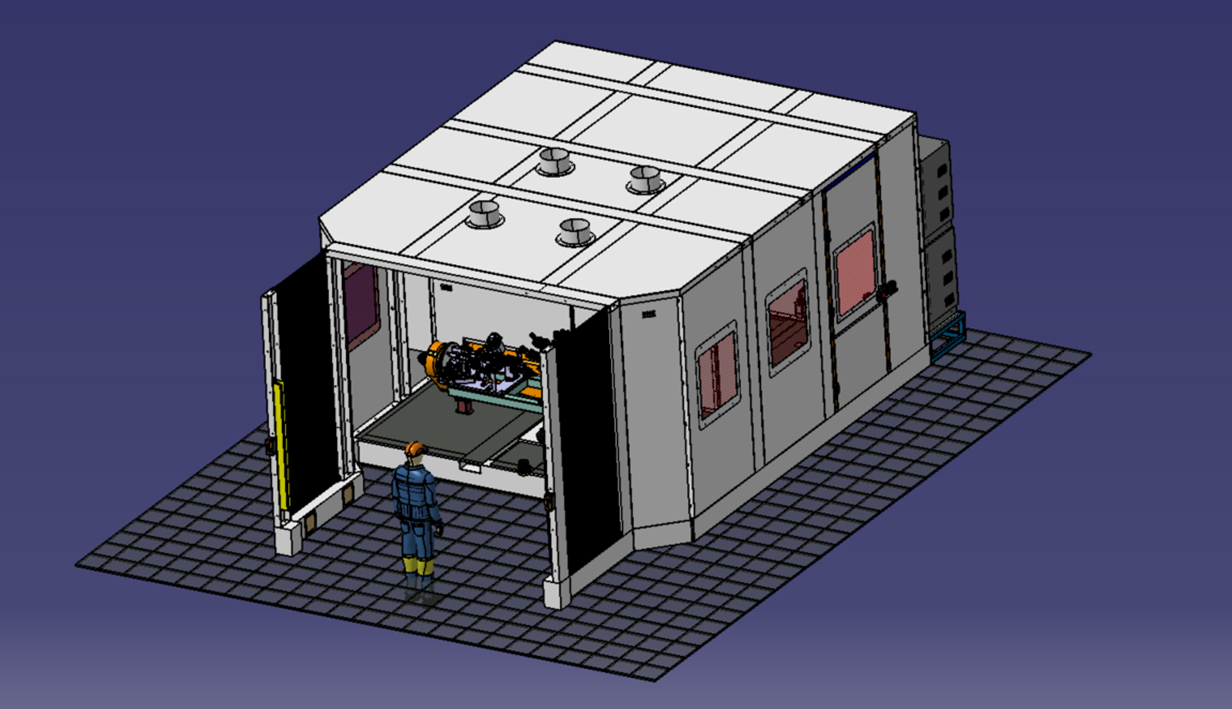

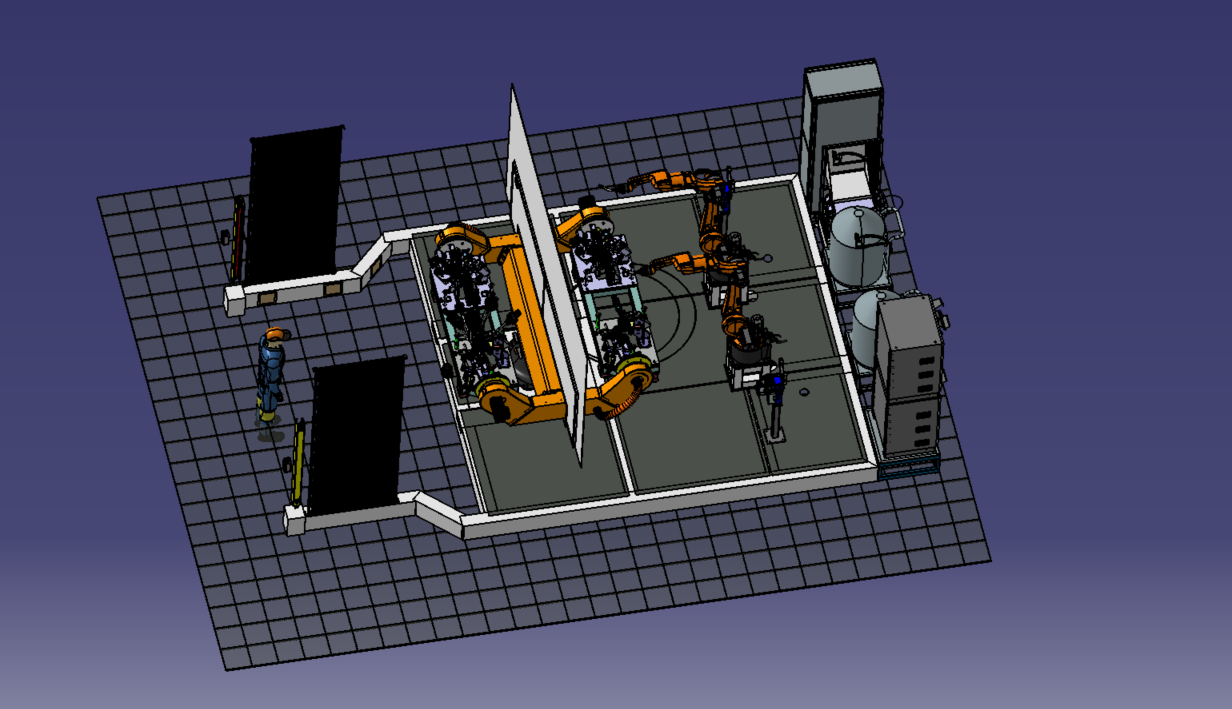

Within the scope of this engineering study, detailed process design, reachability analyses, and welding scenario engineering were carried out for a robotic GMAW welding cell consisting of two industrial robots and one servo-controlled positioner.

Process Engineering in Robotic Welding Cell Design

One of the most critical stages in robotic welding cell design is the proper positioning of parts and the accurate analysis of robot working envelopes. In this project, the following elements were thoroughly planned and validated within a simulation environment:

Synchronized operation scenarios of dual robots

Positioner rotation strategies aligned with part geometries

Collision analyses

Welding accessibility optimization

Cycle time improvement studies

This engineering approach ensured maximum utilization of robot working areas while maintaining stable and repeatable welding quality.

Impact of Positioner Integration on Welding Quality

In robotic GMAW applications, positioner systems directly influence welding quality by maintaining the workpiece in the optimal welding orientation. With the integration of a servo-controlled positioner:

Weld seam continuity is improved

Operator intervention is minimized

Robot access angles are optimized

Welding deformation risks are reduced

As a result, both production quality and overall manufacturing speed are significantly enhanced.

Engineering Approach in Industrial Robotic Welding Cell Design

The successful implementation of robotic welding cells in modern production facilities requires more than selecting the appropriate robot. Cell design must integrate mechanical design, fixture engineering, process optimization, and reachability analysis within a unified engineering approach.

In this engineering study, the following aspects were handled holistically:

Robot reachability simulations

Welding sequence optimization

Cell layout design

Positioner capacity analyses

Process safety evaluations

This integrated methodology resulted in a robust design structure that enhances production performance and operational reliability.

Importance of Robotic GMAW Systems in Industry

Robotic Gas Metal Arc Welding cells are indispensable systems for automotive and railway manufacturers engaged in high-volume production. These systems ensure both quality consistency and cost optimization.

A properly designed robotic welding cell enables:

Standardized production quality

Reduced cycle times

Lower operational error rates

Increased production line efficiency

Optimizing robots, positioners, and fixture systems together in industrial automation projects is one of the most critical factors determining long-term production performance.